Everything You Need To Know About The Different Fuse Types And Their Importance

Different Fuse Types And Their Importance – Since humans began installing electronic connections, such as headlights and phones, inside automobiles, using Fuse has become a necessary component. These innovative gadgets protect your automobiles against electrical problems, power overloading, and accidents.

Several fuse types are accessible on today’s market, from original equipment manufacturers to aftermarket providers. So, in this article, I will guide you on Fuse with its unique purposes.

Why Use a Fuse?

This prevents the overloading current from passing through the circuitry to much more costly components. Fuses may also contribute to UL and NEC compliance for your device’s control systems. Furthermore, these weren’t the only technologies you may employ to safeguard your equipment from excessive electric current. There are several alternatives, such as circuitry breakers and safety relays, but here are different fuse types you should know once you decide to use them.

Different Fuse Types and their purpose

Bottle Type Fuse

There are two main types of bottle-type, which have different-sized ends. The bigger end of this Fuse is proportioned to match the adapter screw sockets, ensuring that you did not place the incorrect Fuse further into circuits.

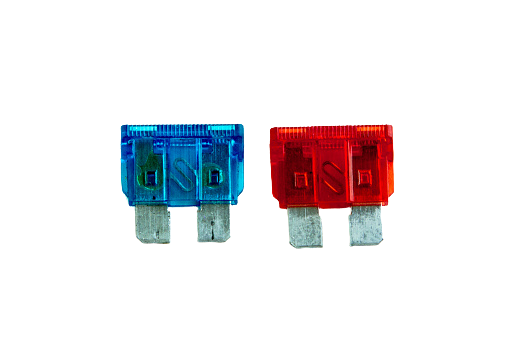

Car Type Fuse

A Car Type fuse, which is commonly known as automobile fuses, protects the automobile’s electronics against overload and circuit spikes. Car Fuse is a low-cost safety technology that safeguards your car’s circuitry, connections, and components. Fuse is essential for the safety of either drivers or passengers because of the growing number of electrical components within automobiles.

Cartridge Type Fuse

A cartridge fuse provides electronic circuit and equipment overloading prevention. Its contact point is located at either end of the cylinders’ cylindrical form. Ceramics, glasses, or ceramics are the most common materials for a cartridge fuse.

Non-Resettable Fuse

Whenever a problem is identified, a non-resettable type of Fuse interrupts the flow of electricity, protecting critical internal components. This Fuse was developed to be attached to a PCB using a direct soldering process (PCB). Throughout this single-use type of Fuse, two lines protrude from the fused core and are not contained inside the body.

Offset Tag Fuse

This type of Fuse has identifiers that protrude from both ends of a cylinder shape body. The Fuse’s intended usage determines the location of its tags. Circuits utilize fuses as a critical point to prevent overcurrent and tripping. Its metallic strips inside the fuse melt if the voltage becomes too high, resulting in circuit breaks.

Resettable Type Fuse

Several implementations for reusable circuit safety devices called resettable surfaces to fuse. A resettable fuse will break whenever the voltage is too high yet resumes operation once the situation is back to normal.

Square Body Fuse

A Square Shape Fuse is an exceptionally dependable and fast-acting fuse that safeguards semiconductors. A type of Fuse that is meant to safeguard sensitive equipment like SCRs, thyristors, and also diodes are usually called “high-speed.” Maximum peak voltage let-through and spike voltages are minimized by using these technologies.

Tag Type Fuse

A Tag Type fuse is developed primarily for general industrial settings and applications, such as the distribution of powers and engine security. A tag-type fuse is distinguished through metal labels that extend out from the endpoints of the fuse body either in a centralized or offsetting orientation.

Thermal Type Fuse

A Thermal type fuse, commonly known as thermal cutoffs, was an advanced safety device utilized in electrical wiring to prevent the sudden overheating of equipment. This Fuse is typically offered in axial or radial packages, while some are now accessible as chips.

Conclusion

An electrical fuse is necessary for your safety since they instantly stop electricity when a substantial temperature rise triggers the filaments within to break. Without this advanced safety mechanism, a constant temperature spike might lead all lines and wires to break and ignite, resulting in a disaster or a tragedy.

Also Read What are electronic counters?